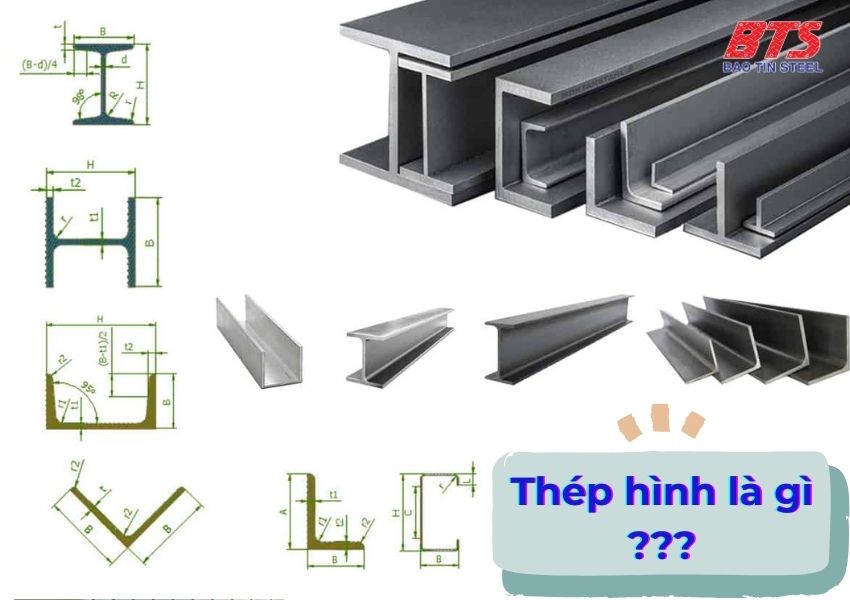

Structural steel, also known as shape steel, is a familiar material in the construction industry, yet not everyone fully understands its characteristics, classifications, and applications. This article provides detailed information about structural steel to help you gain a clearer understanding of this important material.

What is Structural Steel?

Structural steel, also called “shape steel,” is a construction material with cross-sections shaped like letters (I, U, V, H, etc.). Made from an alloy of iron, carbon, and other chemical elements, structural steel offers high hardness, strength, and load-bearing capacity. It is widely used in construction, shipbuilding, bridges, roads, and factories.

📌 Note: The correct English term is “shape steel” or “structural steel,” not simply “steel profile” as translated by Google.

Structural steel is manufactured from high-quality steel using advanced technology and international standards such as JIS (Japan), ASTM (USA), EN (Europe), and GB (China). Thanks to this, it has several outstanding advantages:

- High durability: Withstands heavy loads and strong impacts.

- Good workability: Easy to bend, cut, stretch, or twist.

- Corrosion resistance: Suitable for harsh environments.

Types of Structural Steel

Currently, there are six popular types of structural steel on the market:

I-Beam (I-Shaped Steel)

- Cross-section resembles the capital letter “I”.

- Known for vertical load-bearing capacity and good bending resistance.

- Often confused with H-beam.

- Difference: I-beam flanges are shorter than the web height, while H-beam flanges are nearly equal in size to the web.

- Applications: Used for beams, columns, and purlins in construction projects.

H-Beam (H-Shaped Steel)

- Cross-section resembles the capital letter “H”.

- Flange width is almost equal to the web height.

- Classified into wide-flange, narrow-flange, and medium-flange beams.

- Applications: Structural frameworks for large-scale projects, bridges, and factories.

U-Channel (U-Shaped Steel)

- Cross-section resembles the letter “C”.

- Applications: Purlins, roofing structures, machinery, and household equipment.

C-Channel (C-Shaped Steel)

- Cross-section resembles the letter “C”.

- Widely used in large-scale construction projects.

- Main material for manufacturing machinery, household appliances, and furniture.

L-Angle (L-Shaped Steel)

- Cross-section shaped like the letter “L”.

- Two perpendicular sides with different lengths.

- Weight per meter is calculated based on nominal size and steel density (7.85 kg/dm³).

V-Angle (V-Shaped Steel)

- Also called V-angle steel.

- Two equal legs form a “V”-shaped cross-section.

- Applications: Reinforcement, structural frameworks, and corner strengthening.

Manufacturing Process of Structural Steel

The production of structural steel goes through the following stages:

- Ore processing: Selection of iron ore, coke, and limestone.

- Molten steel production: Heating raw materials in a blast furnace.

- Casting: Producing billets, slabs, or blooms.

- Hot rolling: Rolling billets through rollers to achieve the desired shape.

- Finishing: Cutting, punching, or grooving as required.

- Quality inspection: Ensuring compliance with standards before delivery.

Applications of Structural Steel

In construction

- Beams, columns, and purlins for warehouses and factories.

- Structural frameworks for bridges, culverts, and guardrails.

- High-rise buildings: load-bearing frames, partitions.

In industry and agriculture

- Machinery frames and casings.

- Beams and frameworks for ports and greenhouses.

- Shipbuilding applications.

In household use

- Door and gate frames.

- Railings, shelves, and racks.

Conclusion

This overview has provided insights into structural steel. Understanding its characteristics, classifications, and applications will help you choose and use this essential material more effectively.